PACK UP THE MICROS

PET clamshells / Valery Rizzo

Conclusions from our sustainable microgreens packaging research + development project funded by Sustainable Agriculture Research & Education (SARE)

Farmers and other food producers rely on packaging to keep produce fresh, safe, and attractive to customers. These days, the most common method is single-use plastic packaging. Brooklyn Grange microgreens are currently packed into plastic clamshells because they’re lightweight, inexpensive, and easy to use. We use about 30,000 clamshells a year! The clamshells we use for microgreens are made of thermoformed PET (#1 plastic). Technically PET is recyclable, but in NYC only half of recyclable products are diverted from trash. It is more difficult to recycle rectangular clamshells than plastic bottles, so not all recycling streams accept clamshells. In addition to low diversion rates, plastic recycling has an overrated reputation for environmental benefit. Between all these limiting factors, alternative waste streams that are more available, less energy intensive, and less polluting should be sought out.

Every fall, our farmers circle up to evaluate our growing practices and to discuss areas of improvement, and plastic consumption is at the top of our list every year. It’s been on our minds a long time, and we knew finding an alternative for microgreens would be tricky. Micros and leafy greens are delicate and have a naturally short shelf life, and plastic does a really good job preserving them. With the support of Northeast SARE, Brooklyn Grange was able to invest time and resources into seeking out more sustainable packaging options. We knew that we weren’t the only farmers struggling to find a more sustainable solution and we were eager to share our findings with our farming community. During this year-long project, we investigated what alternative products were on the market, tested four options ourselves, and got feedback from customers.

The main goal of this research was to switch to a better option for the environment than the PET clamshell. The biggest problem we came across was this: there isn’t a real solution! Not yet, at least. Of the many products our team researched and the four products we tested, none were a substantial improvement over our current packaging. To make a real change, we need better composting infrastructure.

WHAT COUNTS AS A GOOD ALTERNATIVE?

After connecting with our farming network and considerable online searching, we chose four products that seemed to best fit our criteria. Our criteria for a “good” product had to balance a few different considerations in these three categories:

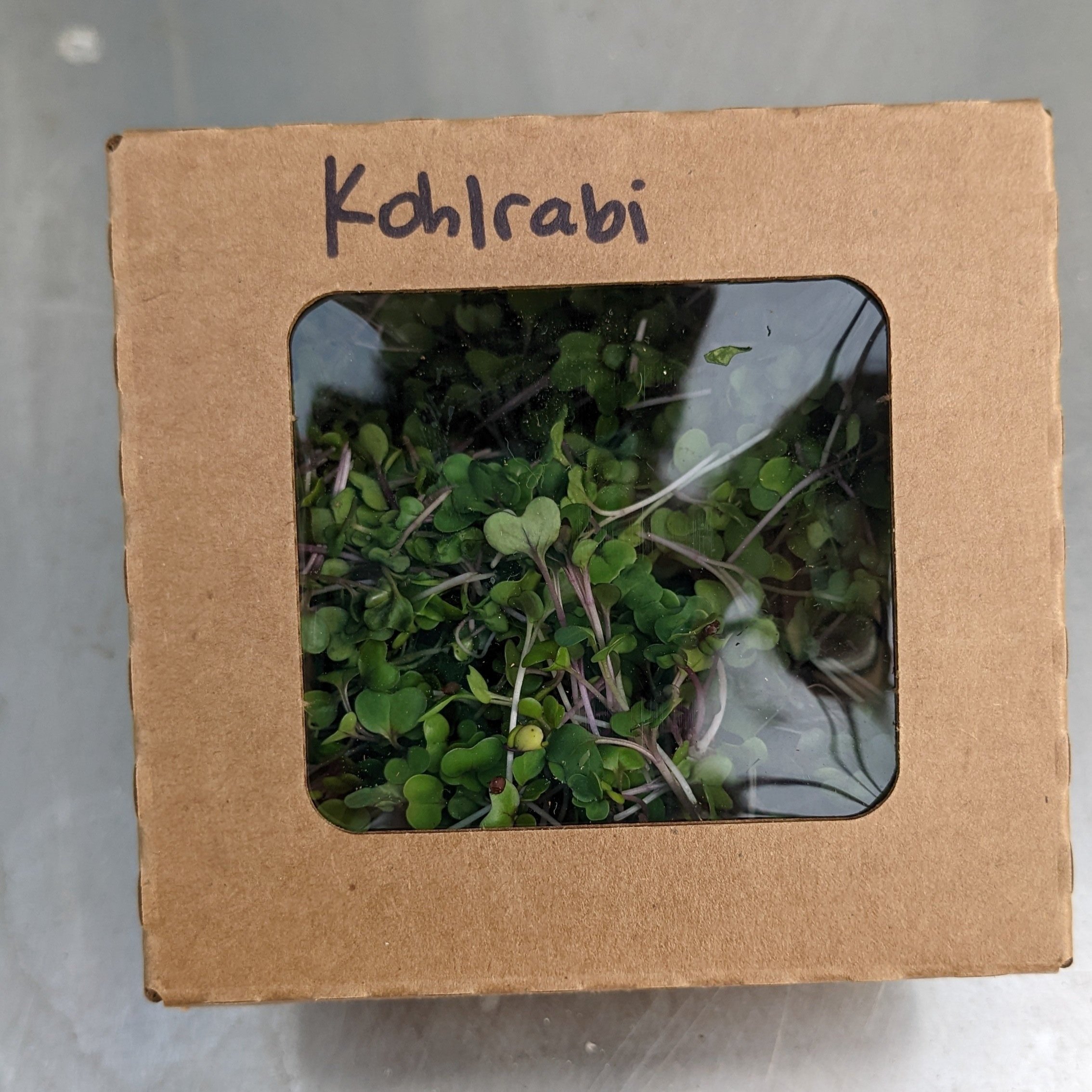

Marketability. Would you buy it? Microgreens are almost always prepackaged, not scooped out of a bulk bin, so the packaging needs to be transparent or have a (plastic) window. No one will buy greens they can’t see.

Operational Viability. Easy and fast to harvest into, stacks well, packs well, transports without damaging the product, shelf life is at least 1 week. Behind the scenes, it’s also important to have a supplier with good customer service, small enough minimum orders, and a workable price.

Environmental Impact. To tackle this category, we simplified the many considerations into inputs and disposability.

Inputs: materials, energy, and water used in manufacturing, pollution from manufacturing, transport, etc.

Disposability: we decided to focus on compostable packaging options. As a process, composting is typically more regional, less energy intensive, and produces fewer emissions than plastics recycling.

The PET clamshells Brooklyn Grange uses currently score great in marketability and operational viability, but fall short in every way in environmental impact.

FOUR ALTERNATIVES WE TESTED

Each alternative we tested is distinctive in its materials and appearance because we wanted to try a range representative of the current packaging market. For each option, we ran a trial with our friends at The Meat Hook for a retailer’s perspective, some regulars at our stand at McGolrick Market, and our microgreens team in the greenhouse at the Sunset Park farm. Shout out to our McGolrick customers who traded surveys for free micros! Product by product, here’s what we found out.

Alternative 1- Good Natured: The Bioplastic Clamshell

Alternative 2- Ready Cycle: Cardboard Clamshell

Alternative 3- Grounded: Bioplastic Pouch

Alternative 4 - Biotre: Kraft Paper Pouch

1. GOOD NATURED: THE BIOPLASTIC CLAMSHELL

On the surface, these bioplastic clamshells seem to meet all our criteria. They look very similar to PET clamshells, so they are definitely marketable. The per unit price isn’t too high, and the process for packing the clamshells is pretty similar to PET clamshells. Bioplastic in this case refers to polylactic acid plastic (PLA) derived from wheat fiber, which is a renewable resource.

These clamshells came with a minimum order of a 200-unit case, so we had the chance to really try them out on scale. These clamshells don’t stack or pack very well, which means they are challenging to use efficiently in the greenhouse. Inefficiency on top of a higher price is a drawback of every product we tried though. The real dilemma with this bioplastic option was wondering, is it actually more sustainable than PET?

Wheat straw fiber needs to be heavily processed to be made into plastic. That process is actually comparable to making PET, with regards to energy use and pollution. It’s hard to compare the exact clamshells – that information is not public – but it’s not a stretch to say bioplastics have a substantial footprint.

After a clamshell is made, transported, and used, it gets thrown out. The waste stream is a big part of the clamshell’s environmental impact. The Good Natured bioplastic clamshells are certified compostable, which in the USA usually means “compostable in municipal and industrial composting facilities” within 180 days. If only half of New Yorkers recycle, how many knowingly have access to a big municipal compost system? The number is growing but still vanishingly small.

When most of our customers may not be able to actually compost this product, which is itself of questionable origin, it felt disingenuous to switch to a bioplastic clamshells.

2. READY CYCLE: CARDBOARD CLAMSHELL

We were inspired to trial Ready Cycle clamshells by our neighbors, Smallhold, a mushroom farm that got its start near our farm at Brooklyn Navy Yard. This cardboard clamshell looks boxier than our PET clamshells, but it has its charms! It comes fully constructed, unlike some competing brands of cardboard clamshell, and it looks like what it is: a consciously chosen eco-friendly product.

We tried the 4 oz clamshell, which is 98% Kraft cardboard and 2% plastic film. Kraft is a specific type of paper product made by removing lignins from wood pulp to increase the paper’s strength. Brown paper shopping bags are a familiar example of Kraft paper, which does break down easily in a compost pile. The remaining plastic film is probably acetate, based on its burn and acoustic properties. Acetate is a cellulose-based plastic and is likely biodegradable, though we did not test that ourselves.

Some produce needs airflow to preserve freshness, and for something like mushrooms, Ready Cycle clamshells are perfect. They also work very well for live microgreens, which we tested briefly. (CSA members at Sunset Park, keep your eyes peeled this spring!) For microgreens that are pre harvested, that airflow is a killer – even our hardiest pea shoots only lasted a day in them. When we contacted the Ready Cycle team, it seems as if they may develop a more enclosed product line which might be appropriate for microgreens and leafy greens. We look forward to trying it when they do!

3. GROUNDED: BIOPLASTIC POUCH

This product is interesting: a clear plastic package which is home compostable. In the US, manufacturers can use a few different stamps to show that a product is industrially compostable. In the EU and Australia, there is a standard for home composting! The Grounded clear pouch meets that standard, and our greenhouse manager tested it in her 30 gallon backyard compost barrel. Impressive.

The base materials for the Grounded pouches are 75% petrochemicals, and 25% starch-based bioplastics. This product does really well on some angles of Environmental Impact, and very poorly on others. Still, that’s at least 25% better than PET clamshells – more if you consider how light the pouches are compared to clamshells.

While promising, the team had doubts about the Grounded plastic pouches from an operational standpoint:

Our trial packages held up well, but our team had doubts that soft plastic pouches could protect microgreens from bruising when working at scale.

Poor customer service. Ordering samples was exceedingly difficult.

Huge minimum order that is too risky for a small farm trying out a new product.

Shipping from Australia, susceptible to delays when there are supply chain issues, not to mention halfway across the globe!

It’s very cool that a clear package could break down in a small compost pile! But the operational concerns were significant, the manufacturing process is not promising, and ultimately the risk was not worth it.

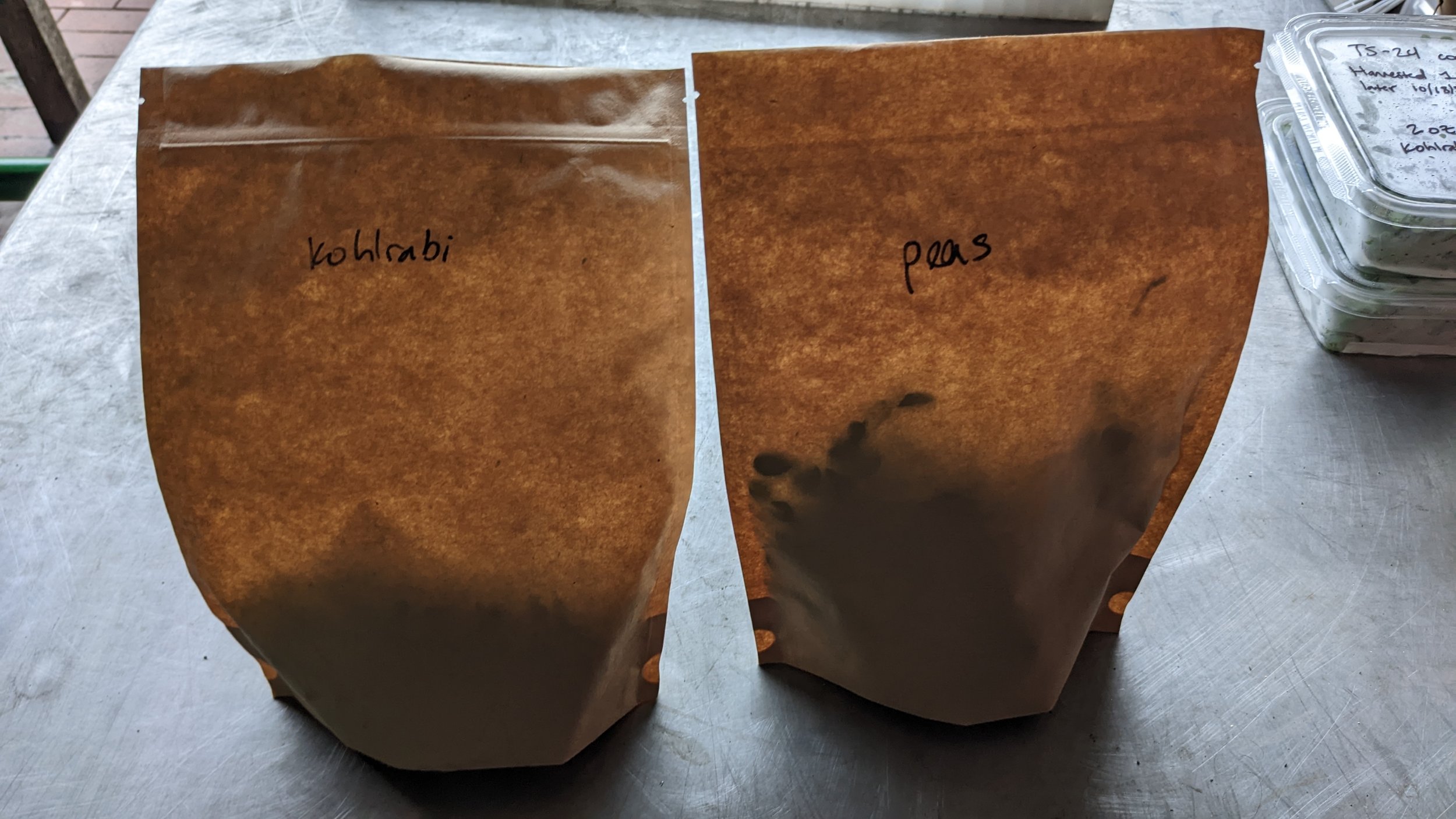

BIOTRE: KRAFT PAPER POUCH

This brown paper pouch is the only product we tested without a window, and that makes it less marketable for prepackaged produce. Nonetheless, we were curious to try a bag-style product with more rigidity (more protection) than the clear Grounded pouches or the lightweight Tug and Totes you might find in the produce aisles.

The product description is somewhat misleading: the manufacturer claims the composting standards ASTM D-6868 and D-6400, but only for 60% of each pouch. The remaining 40% is a PET lining which “an additive that is designed to make it disintegrate significantly faster than standard plastic” with no further information on whether that additive is safe, and whether the disintegration is biodegrading – back to basic organic molecules – or just breaking down into microplastic, a type of pollution.

The Biotre pouches did work to preserve and protect microgreens – they held up well at market and preserved freshness a day or two longer than the clear pouches. However, no window and uncertainty about how the PET would respond to a compost pile did not make this a good alternative.

CONCLUSION

Most farmers are unwilling or unable to take the risk and switch to new types of packaging. Plastic clamshells are the industry standard for a reason: they’re cheap, easy to use, and work well to display and preserve delicate produce. Our farm team was eager to finally be able to put time and care into looking into viable answers to the question of more sustainable packaging, from the perspective of a small farm. Once a good alternative is found, developed, and proven, we’re confident that many farmers will gladly make the switch.

As of spring 2023, we could not find a packaging alternative to swap in for harvested microgreens. Even bioplastic clamshells, which seemed like the easiest switch, run into serious issues with environmental impact during manufacturing, and consumer access to industrial scale composting. The other products we tried run into similar issues, plus operational barriers. To switch to a product containing bioplastics in good conscience, we would want to see improvement in a few areas:

Clean manufacturing

Consumer access to industrial scale compost

Consumer education around industrial scale compost

Transparency in composting standards and certifications

None of those barriers are insurmountable! But it’s more than one small farm can chew. A different way of approaching the packaging question would be to change up our growing systems. For example, a grower could use Ready Cycle cardboard clamshells with live micros, or ask customers to bring reusable containers to fill from bulk bins. These switches are not financially viable for us at Brooklyn Grange, but maybe they could be at another farm! Try them out, let us know what you find. We’ll all keep trying things out until we find a solution that sticks!

PET clamshells / Valery Rizzo

PET clamshells / Valery Rizzo

PET clamshells / Valery Rizzo